The global supply chain industry is poised for transformative shifts as we approach 2025. Industry leaders are forecasting significant trends that will redefine supply chain management. A survey by KPMG reveals that CEOs rank supply chain risk among the top three threats to business, underscoring the critical importance of resilience and adaptability in the face of geopolitical tensions and economic instability.

Technological advancements are at the forefront of this evolution. The integration of Industry 4.0 into global supply chains is set to revolutionize operations, with generative AI enhancing demand forecasting, risk management, and predictive maintenance. Notably, a report by EY indicates that at least 40% of supply chain organizations are heavily investing in generative AI, highlighting its growing significance in the industry.

According to a report by Gartner, “the companies ranked in the Supply Chain Top 25 have built solid foundations in digital supply chain data and capabilities,” highlighting the critical role of technology in shaping future supply chains.

The Impact of Recent Disruptions

The past few years have underscored the vulnerabilities within global supply chains. From delays in shipping to shortages of critical components, organizations have faced unprecedented challenges. As noted by Alex Saric, a Smart Procurement Expert at Ivalua, “Tariffs and geopolitical unrest will see new sourcing hubs appear across Asia and beyond,” prompting companies to seek alternatives to traditional manufacturing locations like China. This shift reflects a broader trend towards resilience and flexibility in supply chain operations.

Also, sustainability continues to be a pivotal focus. Environmental, Social, and Governance (ESG) considerations are driving companies to adopt greener practices, with an emphasis on reducing carbon footprints and enhancing transparency. The European Union’s implementation of the Carbon Border Adjustment Mechanism (CBAM) exemplifies the regulatory push towards sustainable supply chains.

In light of these developments, let’s consider the top global supply chain trends to watch in 2025.

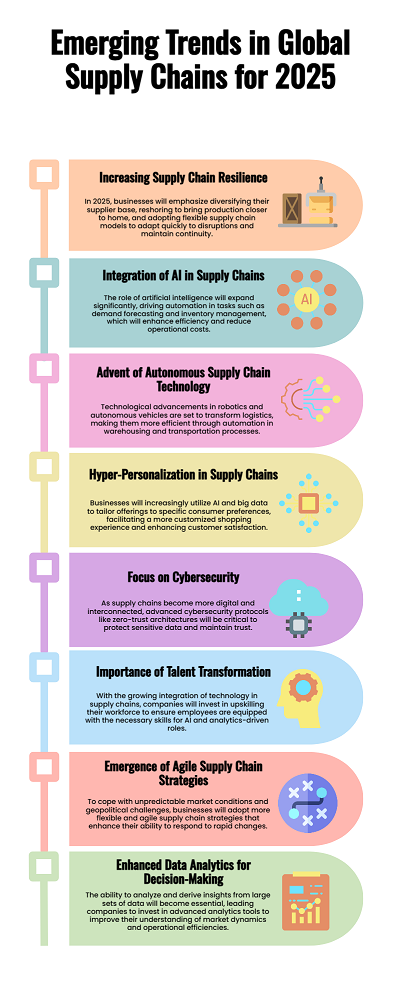

Top 10 Global Supply Chain Trends to Watch (in 2025)

1. Increased Focus on Supply Chain Resilience

The disruptions of 2024, whether geopolitical conflicts, natural disasters, or continued ripple effects from the COVID-19 pandemic, have underscored the need for resilience. In 2025, companies will prioritize diversifying suppliers, reshoring, nearshoring, and creating agile supply chain networks. Digital twins and predictive analytics will play a crucial role in modeling disruptions and optimizing responses.

2. Expansion of AI-Driven Supply Chains

In 2024, generative AI made waves in multiple industries. By 2025, AI will be deeply integrated into supply chains, automating demand forecasting, inventory optimization, and supplier negotiations. Artificial Intelligence (AI) will transition from a tool for automation to a central component of supply chain management. AI systems will optimize logistics, procurement, and planning through predictive analytics and real-time decision-making. Companies that harness AI effectively will enhance efficiency and reduce operational costs while improving responsiveness to market changes.

Advanced AI tools will not only detect inefficiencies but also provide actionable strategies, significantly enhancing agility and operational efficiency.

3. Rise of Autonomous Supply Chain Systems

Robotics, drones, and autonomous vehicles will redefine logistics and warehousing. Drones will handle last-mile deliveries in urban and rural areas, while autonomous forklifts and trucks will reduce dependency on human labor in warehouses. Integration of IoT with these systems will allow real-time monitoring and rapid issue resolution.

4. Hyper-Personalized Consumer Supply Chains

As e-commerce continues to dominate, businesses will leverage AI and big data to predict and meet individual customer preferences. Hyper-localized fulfillment centers, tailored delivery schedules, and bespoke product configurations will become key differentiators, driven by seamless integration between demand-side and supply-side technologies.

5. Nearshoring and Localized Production

In response to global disruptions, businesses will increasingly adopt nearshoring strategies, relocating production closer to key markets. This trend aims to enhance agility, reduce transportation costs, and mitigate geopolitical risks. Nearshoring will complement existing global supply chains, allowing companies to balance cost with speed and resilience.

6. Talent Transformation and Workforce Upskilling

Automation will shift the workforce landscape. Companies will prioritize upskilling programs to prepare workers for AI, robotics, and analytics-driven roles. Additionally, there will be a demand for specialists in data science, cybersecurity, and supply chain engineering. Attracting talent will depend on companies’ ability to offer flexible, technology-driven work environments.

7. Growing Importance of Cybersecurity in Supply Chains

The rise of interconnected systems, IoT devices, and AI integration increases vulnerabilities. Cyberattacks on supply chains in 2024 highlighted the need for robust defenses. In 2025, businesses will adopt advanced cybersecurity measures, such as zero-trust architectures and blockchain-secured data exchanges, to safeguard their supply chains.

8. Supply Chain Risk Management

In 2025, supply chain risk management is set to take center stage as businesses grapple with increasingly complex and unpredictable challenges. Geopolitical tensions, climate change, economic volatility, and evolving consumer expectations have converged to create an environment where proactive risk management is no longer optional—it is a competitive necessity.

According to a 2024 Deloitte survey, 79% of supply chain executives reported experiencing significant disruptions in the past year, ranging from supplier insolvencies to cyberattacks. These disruptions have revealed vulnerabilities in global supply chains and highlighted the need for robust risk mitigation strategies. Companies will invest heavily in real-time tracking systems powered by IoT sensors, advanced analytics, and blockchain technology. These tools will provide end-to-end transparency, enabling businesses to identify and address potential risks before they escalate.

Also, sophisticated scenario planning tools and AI algorithms will be used to model potential disruptions and develop contingency plans. For example, companies may reroute logistics networks or stockpile essential materials in anticipation of trade restrictions or conflicts.

9. Agile Supply Chain Strategies

Agility will be paramount as businesses face ongoing volatility in demand and supply. By 2025, the adoption of agile supply chain strategies will intensify as businesses strive to navigate volatile demand patterns, geopolitical disruptions, and emerging technologies. Unlike traditional linear supply chains, agile systems prioritize flexibility, speed, and responsiveness, allowing organizations to pivot quickly in response to external shocks and evolving customer expectations.

A McKinsey report from late 2024 found that companies with agile supply chains are 60% more likely to recover from disruptions within 30 days compared to their less flexible counterparts.

10. Enhanced Data Analytics

Data is often referred to as the “new oil,” but in supply chains, it is the foundation for achieving visibility, agility, and efficiency. The ability to analyze vast amounts of data will be crucial for informed decision-making in supply chains. Companies will invest in advanced analytics tools that provide insights into market trends, operational performance, and customer behavior, enabling more strategic planning and execution.

According to a 2024 study by Accenture, companies that utilize advanced analytics in their supply chain operations see up to a 15% reduction in costs and a 25% improvement in service levels.

Conclusion

As we look toward 2025, the global supply chain landscape is entering a pivotal phase of transformation. Each trend—from enhanced data analytics to agile strategies and robust risk management—highlights the growing need for resilience, adaptability, and innovation. The disruptions of recent years have underscored the fragility of traditional supply chain models, while advancements in technology, sustainability, and strategic frameworks offer a roadmap for evolution.

Organizations that embrace these trends proactively will not only mitigate risks but also unlock new opportunities for growth and differentiation.